formally HiDefSpex.

formally HiDefSpex. formally HiDefSpex.

formally HiDefSpex.

We won't be beaten on price, phone us for unbeatable prices!

To order any of the Pilla range simply call us on either 0208 5933502 or 0208 2204733 or pop in to see the full range in stock.

|

Hawk Lenses: Diamond Vision

|

Prices 3 lens set £POA |

|

Puma Lenses: Diamond Vision Temples: Fully Adjustable Rubber |

Prices 3 lens set £POA 1 Lens and frame £POA spare lens £POA |

|

Panther No Post Lenses: Diamond Vision |

Prices 3 lens set £POA 1 Lens and frame £POA |

|

Pather Post Lenses: Diamond Vision |

Prices 3 lens set £POA 1 Lens and frame £POA |

|

HDS 15% LTM Lens: |

Price per shield £POA |

|

The Panther Prescription insert is a large pair of Spex that sits directly behind the shield. As your prescription changes, just change the prescription insert. |

Price £POA |

|

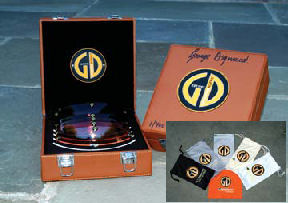

EACH GEORGE DIGWEED SIGNATURE PANTHER IS

SIGNED AND NUMBERED BY THE 15-TIME WORLD

CHAMPION. COMPLETE WITH SPECIAL MICRO

FIBERBAGS AND A CLEANING CLOTH. COMES WITH 5 LENSES. |

Price £POA |

1. HDS Diamond Vision Lenses are made of a bullet-proof lens material that has an impact resistance which is superior to Polycarbonate. HDS Diamond Vision Lenses absorb energy without permanent deformation and maintain good visual acuity when impacted with a mass.

3. HDS Diamond Vision Lenses are not sensitive to Stress Cracking. Polycarbonate, however, will crack under local pressure. Our Diamond Vision Lenses are guaranteed for life from breakage.

|

||